A vibrating feeder is a

critical, high-efficiency material handling machine designed to continuously and

evenly convey bulk, granular, or powdered materials—such as ores, cement,

grains, or chemical raw materials—from hoppers, silos, or bins to downstream

processing equipment like crushers, screens, or mixers. Although the structure of the vibrating feeder is quite simple, it can vary greatly depending on different application scenarios. This article will take you through the types of vibrating feeders.

1. Motor Vibrating Feeder

The motor vibrating feeder is a high-efficiency industrial machine that uses vibration motors as the excitation source to convey bulk materials. It uniformly, continuously, and quantitatively feeds loose materials such as blocks, granules, and powders from storage bins or hoppers to downstream equipment like crushers, screens, or conveyors. Featuring a simple structure with core components including a trough, vibration motors, and shock-absorbing springs, it supports both suspended and seated installation for adaptability to complex working conditions. With adjustable vibration intensity and frequency via optional frequency conversion motors—it ensures stable and sensitive feeding while offering low maintenance costs and long service life. Widely applied in mining, metallurgy, coal, construction materials, chemical, and electric power industries, this reliable feeder enhances production line efficiency by preventing equipment blockages and stabilizing material flow.

Features

1. Large feeding capacity

2. Simple

structure & easy maintenance

3. Strong adaptability

4.Low

energy consumption

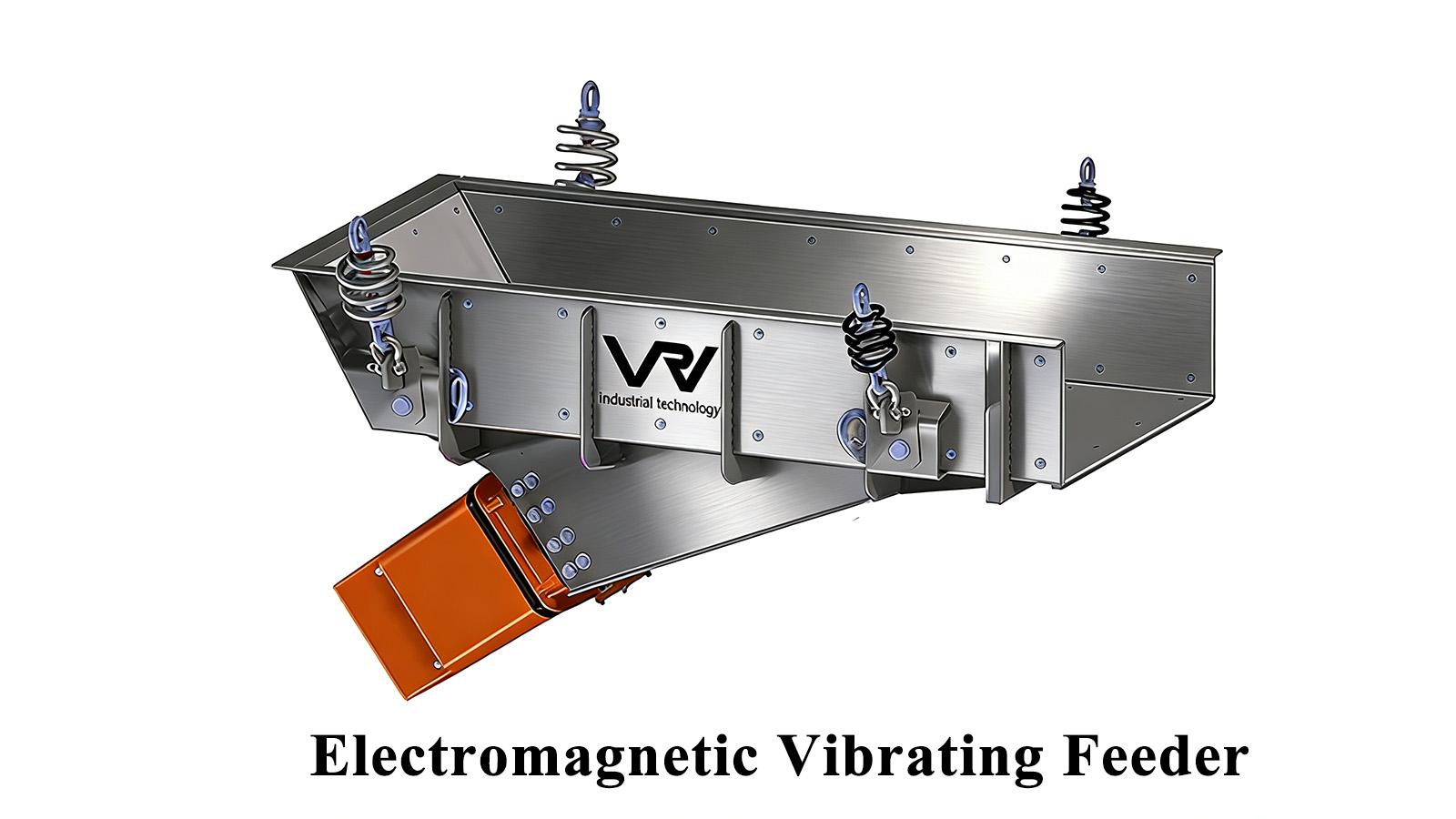

The electromagnetic vibrating feeder is an automated feeding machine that drives the tray or tube to vibrate reciprocally relying on an electromagnetic vibrator. It can uniformly, quantitatively and continuously convey bulk, granular or powdered materials from the storage bin to the receiving device. It features a simple structure, no need for lubrication, low energy consumption, and stepless adjustment of the feeding amount. It can achieve automatic control of the production process and is widely used in various industries such as mining, metallurgy, coal, chemical engineering, electric power, and grain.

|

Features |

|

1. Precise feeding, stepless adjustment of output. |

|

2. Energy-efficient, low power consumption. |

|

3. Simple structure, easy installation and maintenance. |

|

4. Gentle material handling, low breakage rate. |

|

5. Low noise and dust, eco-friendly operation. |

|

6. Fast start-stop response, suitable for automated systems. |

|

7. No wearing parts, long service life. |

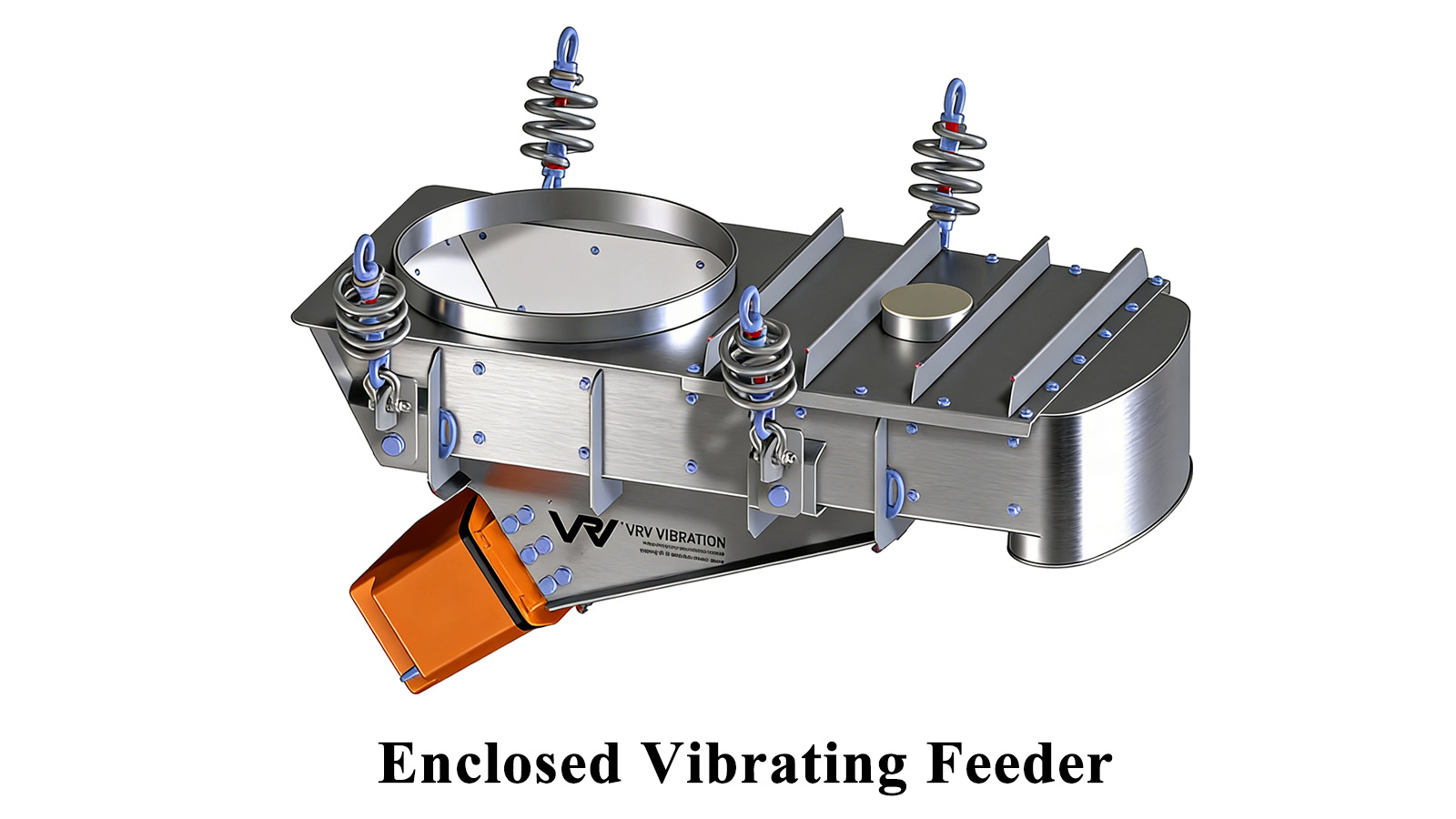

3. Enclosed Vibrating Feeder

The biggest

difference between the closed - type vibrating feeder and the open - type

vibrating feeder lies in whether it has a closed trough structure. The closed -

type vibrating feeder has a sealed trough that can completely enclose the

trough and the material - conveying area. This can effectively prevent dust

from flying during material transportation, reduce noise diffusion, and avoid

external impurities from mixing into the materials. It is suitable for

scenarios in mining, chemical industry, building materials, etc., where

requirements for environmental cleanliness, material purity, or noise control

are high. The closed - type vibrating feeder can use either a vibrating motor

or an electromagnetic vibrator as the excitation source to provide power for

the vibrating transportation of materials.

|

Features |

|

1. Sealed structure:Dust/leakage prevention |

|

2. Stable feeding:Uniform & continuous delivery |

|

3. Low energy consumption:High-efficiency, low power loss |

|

4. Strong adaptability:Multi-material compatibility |

|

5.Easy maintenance:Few wearing parts, easy repair |

4. Compact Vibrating Feeder

The compact vibrating feeder is a material

- conveying device with a small size and a compact layout. It is often equipped

with a pedestal - type electromagnetic vibrator as the power source. Through

vibration, it can uniformly and continuously feed materials such as granules

and powders. It is suitable for production line scenarios with limited space.

It has the characteristics of flexible installation, low energy consumption,

and controllable feeding accuracy. It is widely used in the material pre - treatment

or production transfer links of industries such as mining, chemical

engineering, and food.

|

Features |

|

1. Pedestal - mounted and no additional support is required. |

|

2. Without rotating parts, it has a long lifespan and is maintenance - free. |

|

3. With a compact structure, it takes up little space and is easy to operate. |

|

4. Stable operation |

|

5. High control accuracy and can start and stop without delay. |

|

6. Low noise and low power consumption. |

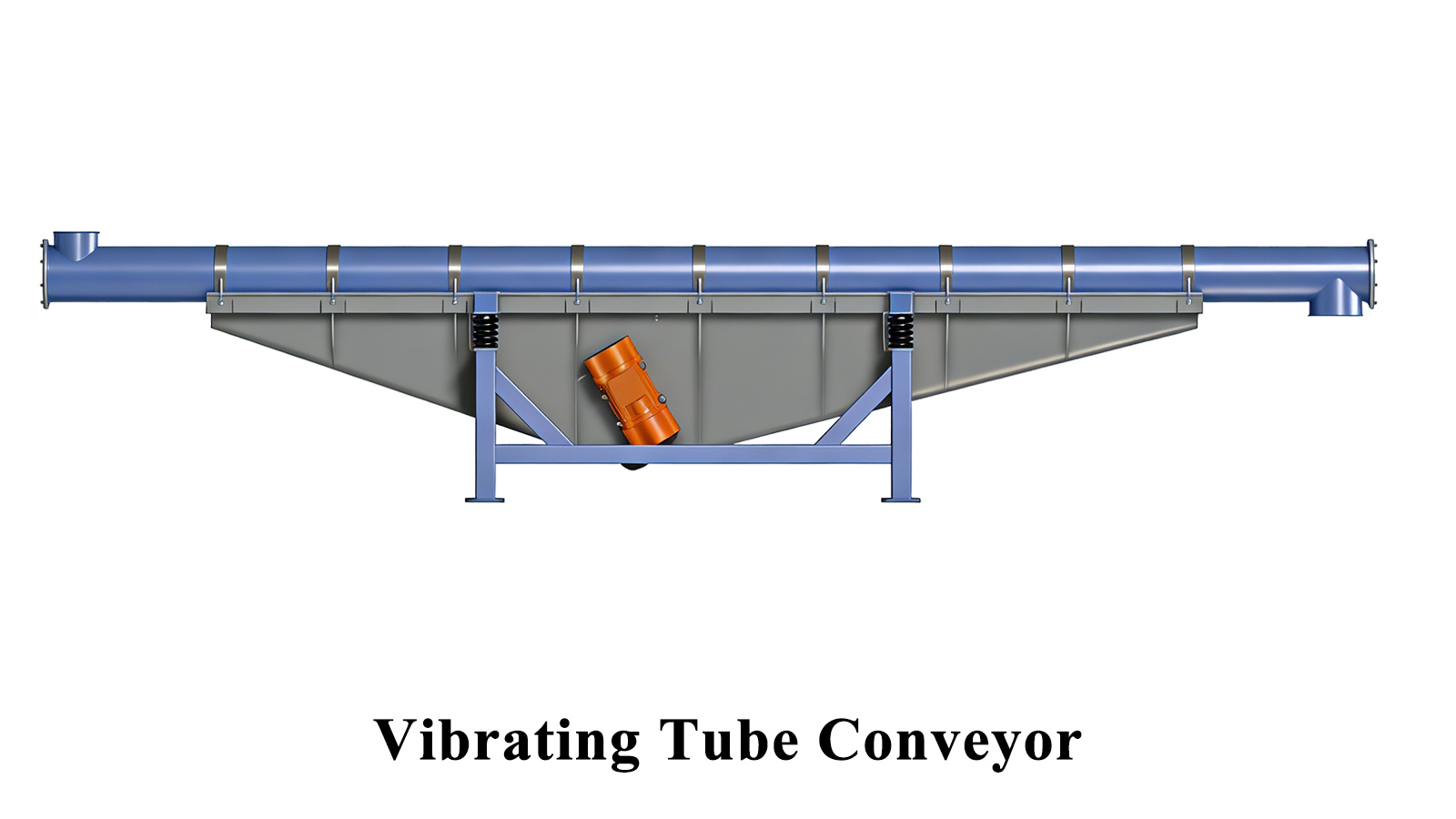

5. Vibrating Tube Conveyor

The Vibrating tube conveyor is a continuous feeding machine powered by vibration. Its core components include a sealed tubular trough, a vibrating motor (or exciter), an elastic support device, etc. The directional exciting force generated by the vibrating motor makes the powdered, granular or small - sized bulk materials in the tubular trough body perform continuous throwing or sliding movements, thus achieving smooth transportation and quantitative feeding from the feed inlet to the discharge outlet. It inherits the advantages of tubular equipment such as dust - tight sealing, a compact structure, and a small footprint. At the same time, due to its vibration - driven characteristics, material blockage is less likely to occur. Moreover, the feeding amount can be precisely controlled by adjusting the vibration frequency or amplitude. Compared with the screw - type tubular feeder, it has no internal rotating parts (such as screw blades), resulting in less wear and easier maintenance, making it more suitable for conveying materials that are prone to adhesion and blockage.

|

Features |

|

1. Continuous feeding: Provides continuous material feeding. |

|

2. Sealed design: Keeps dust in and is dust - tight. |

|

3. Compact structure: Occupies little space. |

|

4. Vibration - driven: Reduces material blockage. |

|

5. Precise control: Adjusts feeding amount via vibration. |

|

6. Low - wear: No internal rotating parts, less wear. |

|

7. Easy maintenance: Simple to maintain. |

แท็ก :

โทรหาเรา :

อีเมล : sales@vrvibratory.com รองรับเครือข่าย ipv6

รองรับเครือข่าย ipv6